Copper pipes for industrial use

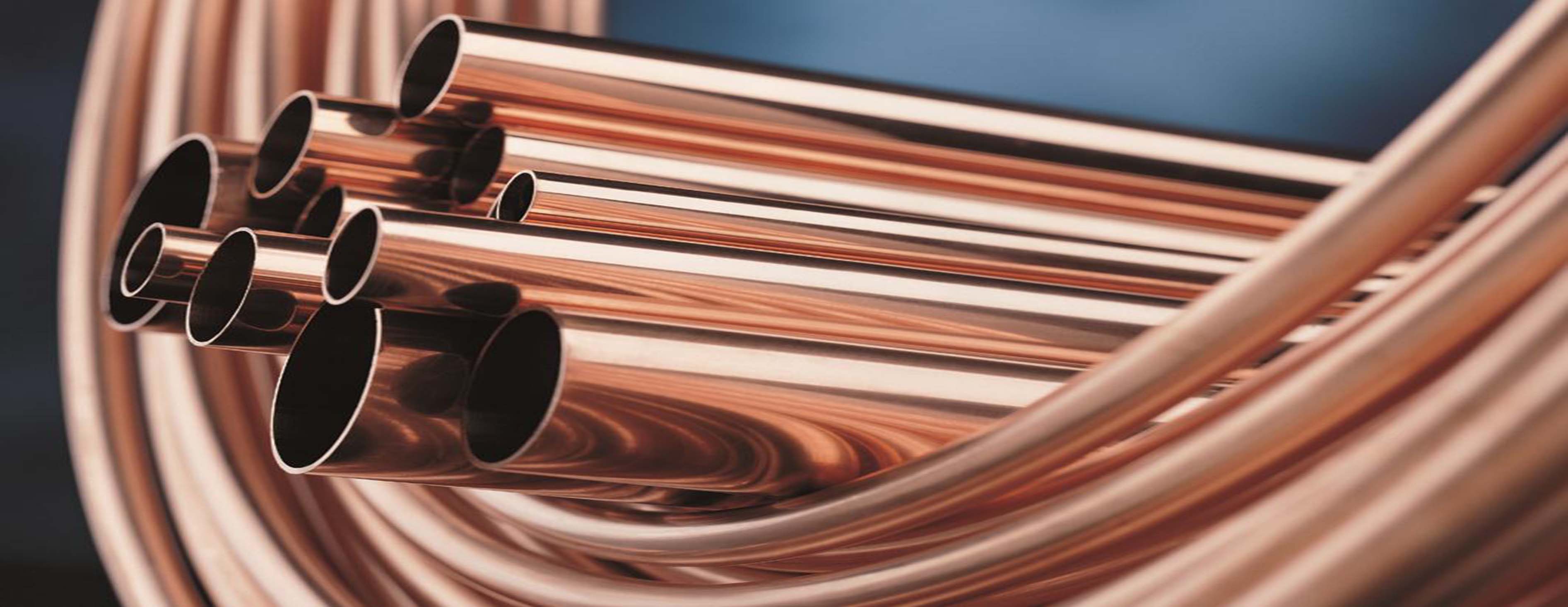

Copper pipes for LPG installations

Product specification: coated copper pipe for LPG

Copper pipe characteristics:

The coated copper pipes for LPG are made with phosphorus dehoxidated copper, quality.

CU-DHP, with the following chemical composition:

Cu + Ag: 99,90% min.

0,015 % ? P (phosphorus) ? 0,040

and comply with the ECE / ONU 67/01 regulation (chapter 7):

1. Gas impermeability: copper is by its own nature.

2. Seamless pipes protected against corrosion: see coating characteristics.

3. Outside diameter of the pipe not over 12 mm and wall thickness at least 0,8 mm.

Coating characteristics:

The PVC coating is made with a polyvinyl resin continuous extruded directly on the copper pipe in a black colour. This coating is to preserve the copper pipes against corrosion effects.

Dimensional characteristics:

Diameter: 6 - 8 mm

Average coating thickness: 1 mm

Coil length (m) 5/10/25/50/other lengths on request

Uses:

LPG installations according to ECE/ONU 67/01.

Packaging:

The number and the total meters per pallet depend upon the coil length chosen at the time of the order.

Remarks:

The approval according to ECE/ONU 67/01 is not required for copper and steel pipes. All the pipes are manufactured within the CUPRUMFOMA Quality System according to UNI EN ISO 9001:2000, certified by Bureau Veritas (certificate nr 194140).