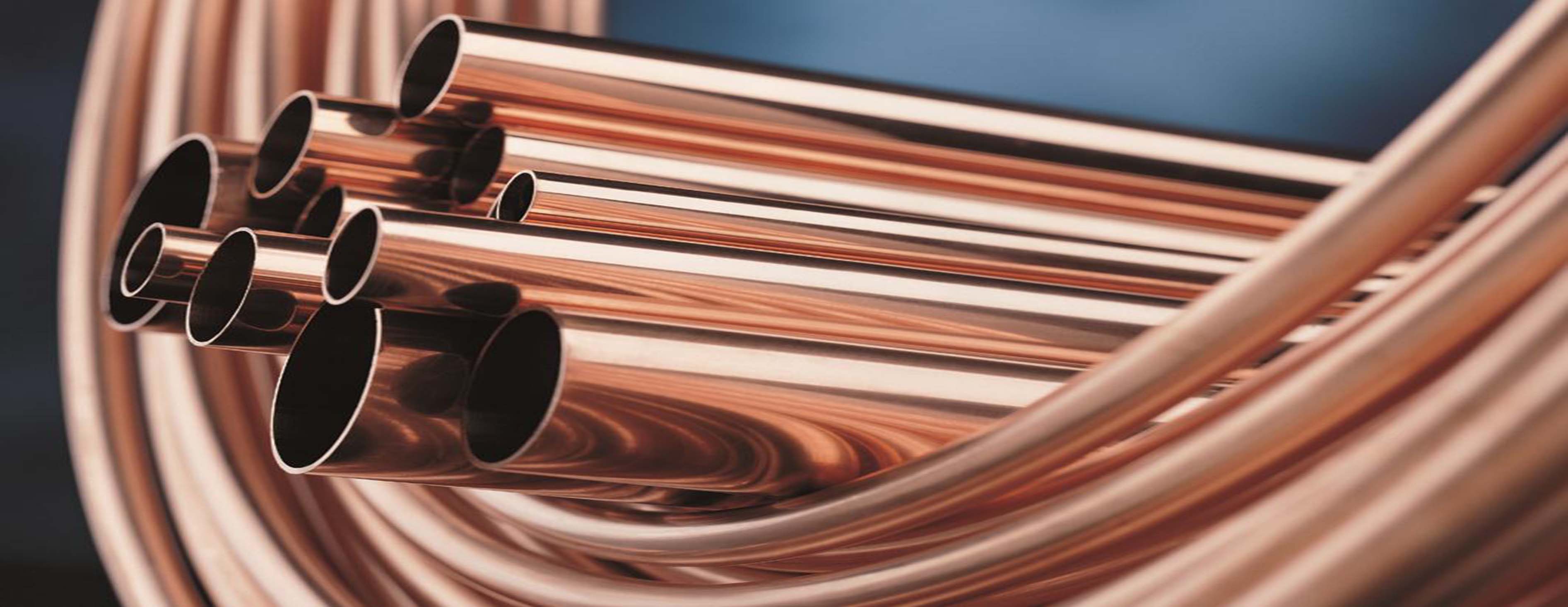

Copper pipes for water, heating and sanitary

Half hard straight lenghts oscar treatment

Further the market request, CUPRUMFOMA some years ago implemented the special OSCAR treatment to protect the pipe from the water corrosivity. By this treatment the pipe has a maximum carbon residue of 0,05 mg/dm2 that means 4 times less of what provided by the CE EN 1057 standard, giving in this way a very high grade of resistance to the pitting corrosion. For this reason our pipes with OSCAR treatment are guaranteed 30 years with a product liability insurance.

| Hard straight lengths production range with OSCAR treatment | ||||

| Dimensions diam. x wall thickness |

Length | Straight lengths per small bundle |

Total mts per bundle |

Approximate bundle weight |

| mm | m | N° | m | kg |

| 6 x 1 * | 5 | 20 | 500 | 70 ca. |

| 8 x 1 | 5 | 20 | 1000 | 200 ca. |

| 10 x 1 | 5 | 20 | 1000 | 250 ca. |

| 12 x 1 | 5 | 20 | 1000 | 300 ca. |

| 14 x 1 | 5 | 20 | 1500 | 500 ca. |

| 15 x 1 | 5 | 20 | 1500 | 500 ca. |

| 16 x 1 | 5 | 20 | 1300 | 500 ca. |

| 18 x 1 | 5 | 10 | 1000 | 500 ca. |

| 22 x 1 | 5 | 10 | 1000 | 500 ca.. |

| 22 x 1,5 | 5 | 10 | 500 | 500 ca. |

| 28 x 1 | 5 | 5 | 500 | 350 ca. |

| 28 x 1,5 | 5 | 5 | 500 | 500 ca. |

° preferrably in wooden cases

In compliance with the specific customer’s requirements, pipes can be produced according to different standardized regulations or, when requested, with different diameters, wall thicknesses and lengths, once the technical feasibility has been verified.