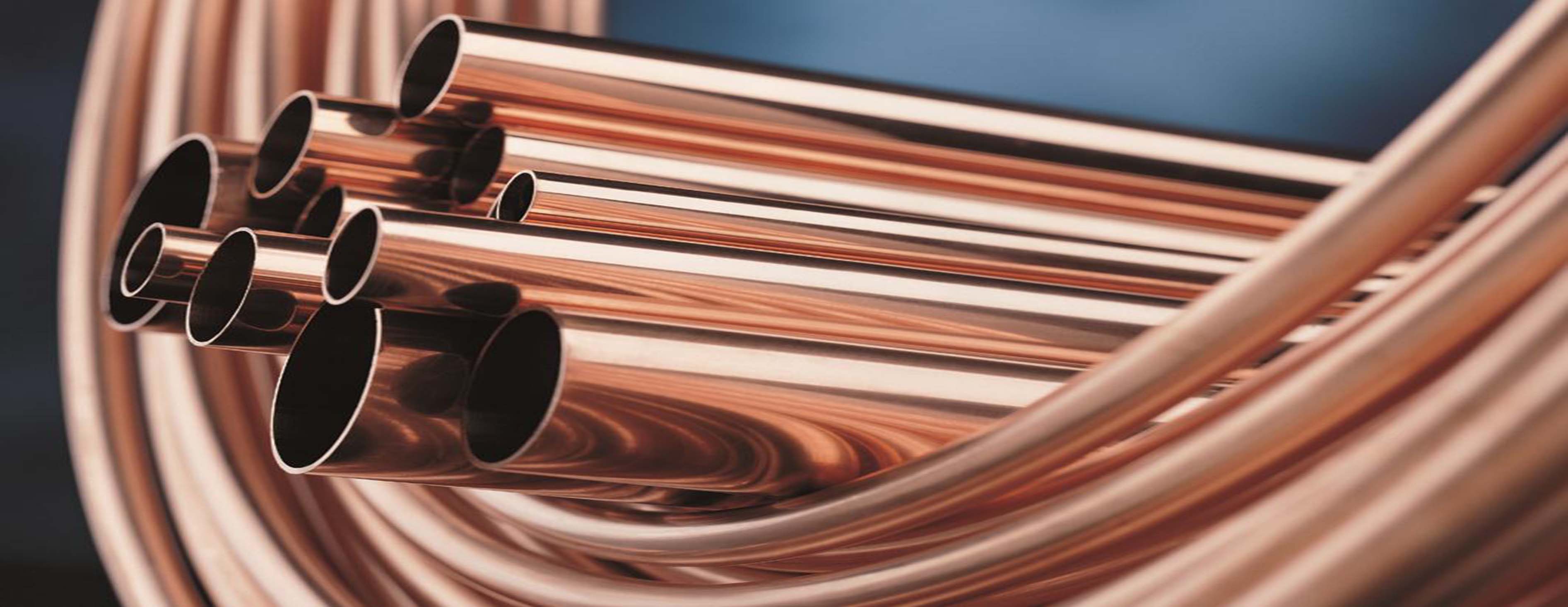

Insulated coils

CLIMAT - Expanded Polyethylene insulation

FrostEn* CLIMAT - Expanded Polyethylene insulation

Insulated pipes for air conditioning and refrigeration

The copper tube CUPRUMFOMA FROSTEN can be used in all plants for air conditioning and refrigeration and it is suitable for the use of refrigerating gas consistent with copper like R407 and R410A.

The in-line production control by defectomat and the continuous control of the external diameter and wall thickness guarantee the maximum safety of the FROSTEN tubes. The tubes are supplied clean, internally degreased and capped. They are produced according to the EN 12735-1 and -2 standards and they also comply with the ASTM B280 specifications.

Copper tube characteristics:

Alloy: Copper Cu DHP 99,90 min.

Dimension and tolerances: according to the EN 12735

Carbon residual: >0,38 mg/dm²

Internal surface smooth and mirror-like

Physical state: annealed (R220)

Excellent resistance to corrosion

Suitable for the new gas R407C and R410A

Use:

Air conditioning and refrigeration plants

Plants with heat pumps

Insulation characteristics:

Expanded polyethylene insulation

in-line extruded on the copper pipe

Produced according to the L 10/91 prescriptions

Colour: Grey*

Insulation thickness: approx. 8 - 10 mm

Fire resistance: self extinguishing Class 1

Marking: by laser at every meter

Odourless and non-toxic - CFC free

Thermal conductivity at 40°C =<0,040 W/m K

Average density: approx. 30 kg/m³

Operating temperature: -30° + 95°C

* * other colours upon request

Packaging:

50 m coils (Ø 22 25m) individually wrapped in film.

Each coil has an identification label with product name, dimensions and length.

Different diameters and lengths can be supplied on request.

| INSULATED TUBES IN COILS FrostEn* CLIMAT | |||||||

| Dimensions od. x w.t. De x Sp. |

Insulation min. thickness |

Coil length |

Coils per pallet |

Total mts. per pallet |

Bursting pressure |

Operating pressure ASTM |

Water content |

| mm | mm | m | nr | m | Mpa | Mpa | l/m |

| 6 x 1 | 8 | 50 | 20 | 1000 | 69,70 | 17,4 | 0,013 |

| 8 x 1 | 8 | 50 | 20 | 1000 | 52,27 | 13,07 | 0,028 |

| 10 x 1 | 8 | 50 | 20 | 1000 | 41,82 | 10,46 | 0,0503 |

| 12 x 1 | 10 | 50 | 18 | 900 | 34,85 | 8,71 | 0,0785 |

| 14 x 1 | 10 | 50 | 18 | 900 | 29,87 | 7,47 | 0,1131 |

| 15 x 1 | 10 | 50 | 18 | 900 | 27,88 | 6,97 | 0,1327 |

| 16 x 1 | 10 | 50 | 16 | 800 | 26,14 | 6,54 | 0,1539 |

| 18 x 1 | 10 | 50 | 16 | 800 | 23.23 | 5,81 | 0,2011 |

| 22 x 1 | 10 | 25 | 16 | 450 | 19,00 | 4,75 | 0,3142 |

In compliance with the specific customer’s requirements, pipes can be produced according to different standardized regulations or with different diameters, wall thicknesses and lengths, once the technical feasibility has been verified.